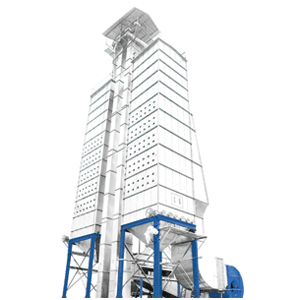

Raw Paddy Dryer

Drying is the process that reduces grain moisture content to a level where it is safe for storage. Drying is the most critical operation after harvesting a rice crop. Delays in drying, incomplete drying or ineffective drying will reduce the grain quality which can result in suffering from losses. MILLTEC Raw Paddy Dryer is used to dry paddy in order to make it safe for storage.

MILLTEC Raw Paddy Dryer does not require any external boiler. Our Raw Paddy Dryer is specially designed to suit various types of paddy grains. These are fitted with systems to help customers monitor and control the drying temperature. It has a hot air blower and furnace to produce the desired drying, which consists of a digital temperature controller to monitor the drying. The uniqueness of this methodology is that it can be operated with husk, firewood, or biomass.

Advantages of MILLTEC Raw Paddy Dryer :

- Designed specially to suit all types of paddy

Stainless steel and Mild steel construction - Optional furnace designs to suit the use of Rice husk, Wood, or Biomass

- Customized designs to make use of steam from the boiler is also available

- Less husk and power consumption, the cost of drying is reduced by 50% compared to steam drying

- Though it is fired by husk or wood, smokeless hot air is extracted directly and hence, odorless drying is achieved

- PLC system to monitor and control the temperature that can achieve up to 160°C

- Drying time approximately 4 hours for 5% moisture reduction

- Minimum civil works, negligible maintenance

Some problems related to incomplete or untimely drying and improper storage is given below :

- Raw paddy must not be stored at a moisture content of above 18%

- A higher moisture content of stored paddy can attract bacteria and damage paddy up to 2-3%

- 2% damage on 3,000 mt amounts to 60 mt/season

- The total damage could be 12 lakhs per annum at the rate of Rs. 20,000/mt

Diesel Burner

Cyclonic Husk Furnace

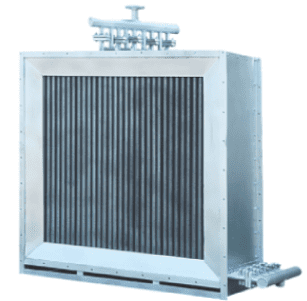

Steam Heat Exchanger

Technical Description

MODEL | CAPACITY (TON) | ROTOR (HP) | BLOWER (HP) | OVERALL SIZE (LXWXH) |

PRDA1 | 6 | 0.5 | 3 | 4 X 2.8 X 5.8 Mtr |

PRDB1 | 8 | 0.5 | 5 | 4 X 2.8 X 7.3 Mtr |

PRDC1 | 10 | 0.5 | 5 | 4 X 2.8 X 8.3 Mtr |

PRDD1 | 12 | 1 | 5 | 3.6 X 3.5 X 9.5 Mtr |

PRDE1 | 16 | 1 | 5 | 3.6 X 3.5 X 10.3 Mtr |

PRDF1 | 20 | 1.5 | 12.5 | 5.6 X 5.5 X 11.6 Mtr |

PRDG1 | 24 | 1.5 | 15 | 5.6 X 5.5 X 12.5 Mtr |

PRDH1 | 28 | 1.5 | 15 | 5.6 X 5.5 X 13.7 Mtr |

PRDI1 | 32 | 2 | 15 | 5.6 X 5.5 X 17.8 Mtr |

PRDJ1 | 40 | 2 | 25 | 6.2X 6.8 X 17.8 Mtr |

PRDK1 | 50 | 3 | 30 | 6.2 X 6.8 X 20.4 Mtr |