The ceramic watch features black bridges, and the titanium features bridges finished in a similar fashion to the rest of the watch, but again, the King Gold sticks out for the immediately noticeable contrast replica watches between the case and the raw finish on the bridges. On all three models, the screws adorning the bezel are left unfinished as well. And of course, they’re not aligned.

Customize feasibility study for your business

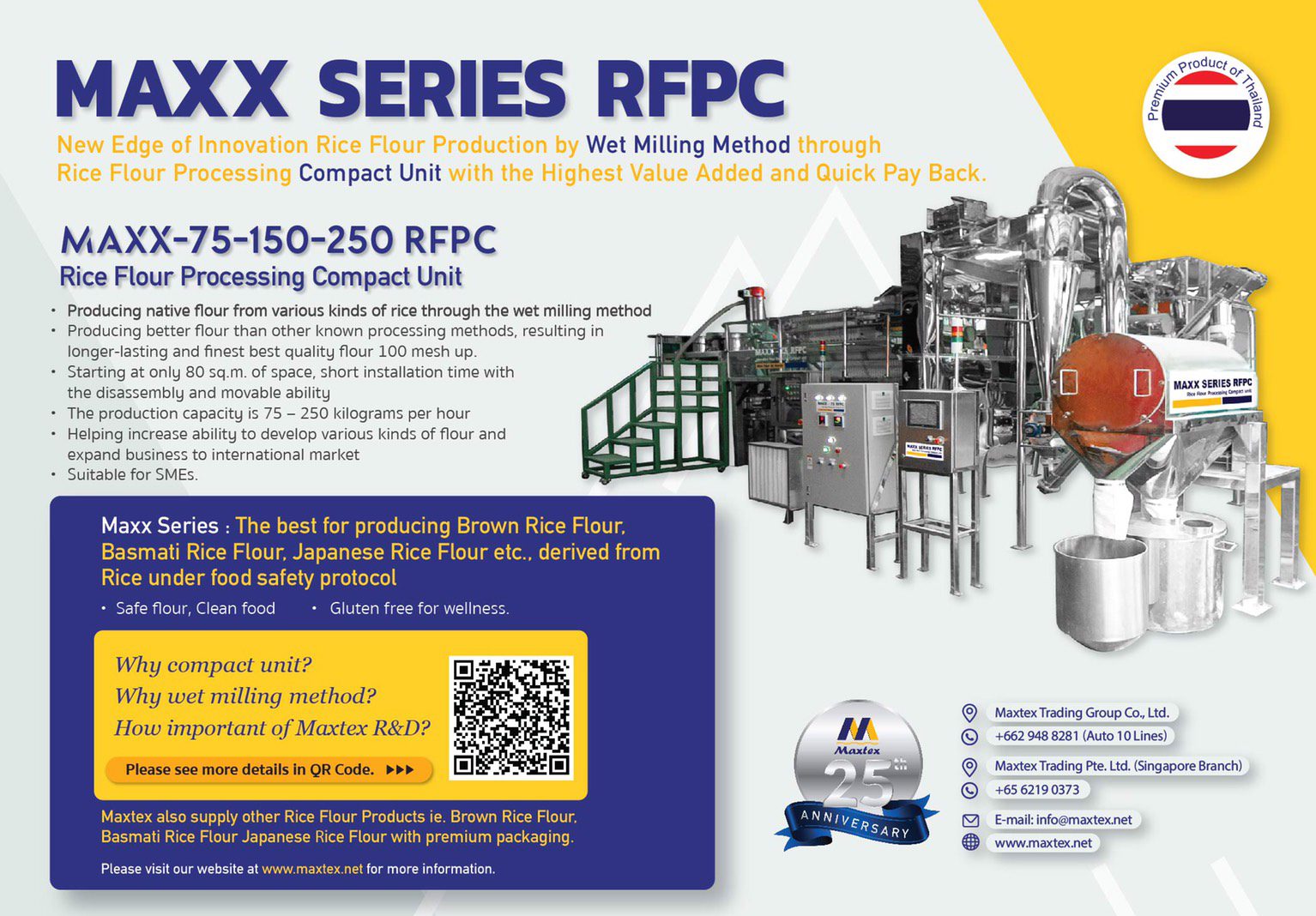

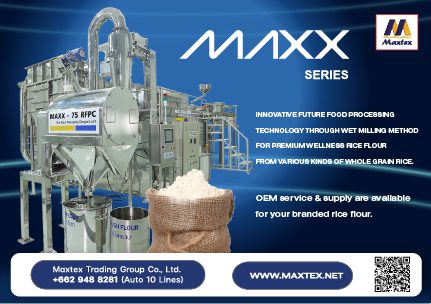

The production capacity is 75 – 250 kilograms per hour.

RFPC The machine can be easily disassembled and moved freely. It is hygienic and suitable for SMEs and startups.

Maxtex unique rice flour turnkey processing compact platform (RFPC) through wet milling method is created from our very own know-how, technology and is entirely made in Thailand. Maxx Series is designed to produce world class processing platforms to process and transform various kinds of rice to rice flour, catering to customers globally. We assure customers and consumers alike will enjoy the best quality products. Customers who purchase Maxx Series will benefit from optimum technology with fantastic advantages such as incredible revenue with high profit margins, multiple value added solutions and quick return on investment.

Thanks to R&D team for their excellent performance, dedication and determination to create and develop to achieve the best product outcome.

R&D team with their unsurmountable knowledge has created and developed many marvelous products for the benefit of the customers and will always continue to create and develop more future products to serve the industry, business partners and consumers alike.

Ein wichtiger Teil des Big Bang Integral-Designs ist die Art und Weise, wie die Bandanstöße rolex replica nahtlos in das Armband übergehen. Dieses einzelne Detail wird mit Zielstrebigkeit und Absicht ausgeführt.

Vinklen dannet af de solide endeled, der møder kabinettet, er ensartet, og der kopi rolex kræves ingen gimmicky visuel teknik for at skjule en uskøn søm. Tingene hænger simpelthen sammen, som de skal. Det er rent.