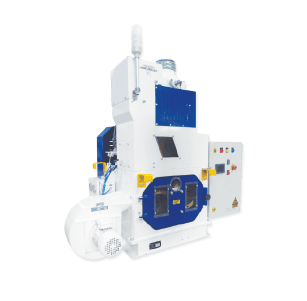

Pneumatic Sheller

Pneumatic Sheller

Pneumatic Sheller is intended to facilitate the easy removal of husks from paddy grains. Input grain is passed between two counter-revolving rollers, which results in the removal of the husk from the grain. This machine is equipped with automatic systems that control the pressure exerted by the rollers, as well as the correct feed rate for the input grains. These are capable of removing husks with a 95% level of accuracy.

The use of pneumatic controls enables a degree of hulling with lesser broken. The lifespan of the rubber rollers is enhanced with the use of an inter-cooling system.

Advantages of MILLTEC Pneumatic Sheller :

- Infinite adjustment of the degree of shelling by adjusting compressed air pressure

- Sensor-enabled panel disengages the rubber rollers automatically when input product flow stops

- Feed rate can be controlled electronically

An inbuilt cooling system to dissipate heat generated on rubber rollers - Auto/manual mode of working

Technical Description

Capacity Ton/hour with Precleaner | Medium Grain 4 TPH |

Motor Power HP/KW | 12.5/9.4 |

Voltage (V)/Frequency (Hz) | 415/50 |

Aspiration | For Suction – 8 For Cooling – 8 |

Weight (KG) | 600 |

Over All Size LxWxH (MM) | 1490 x 1004 x 1341 |