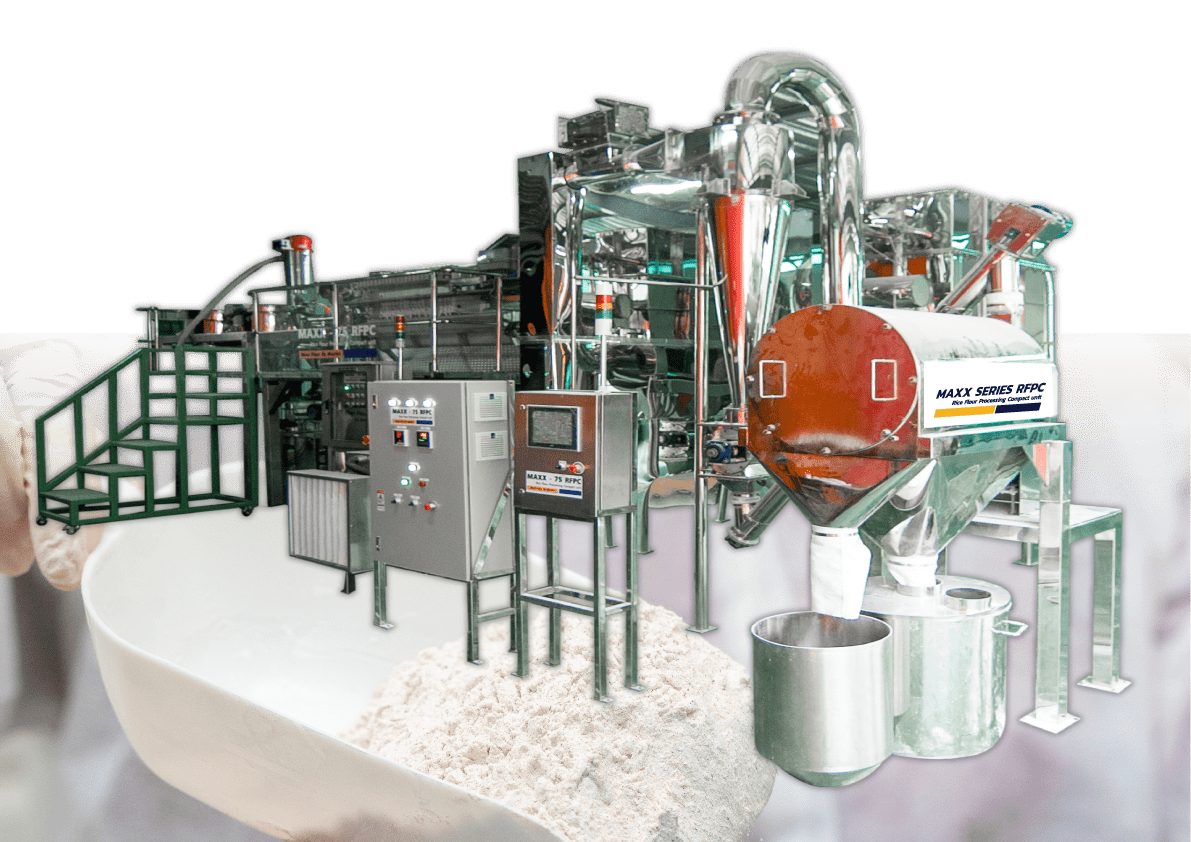

MAXX Series RFPC

Innovation of rice flour production

By wet milling method through rice flour processing compact unit

Able to produce a premium signature product through branding and packaging to create additional uniqueness and nutritional value, such as rice flour with vitamins or essential nutrients.

Able to expand into consumer products in other industries such as mother and baby products, beauty products, and supplements.

Value Added

Processing cheap raw material (i.e. broken rice) into rice flour and help increase the value by more than 180%

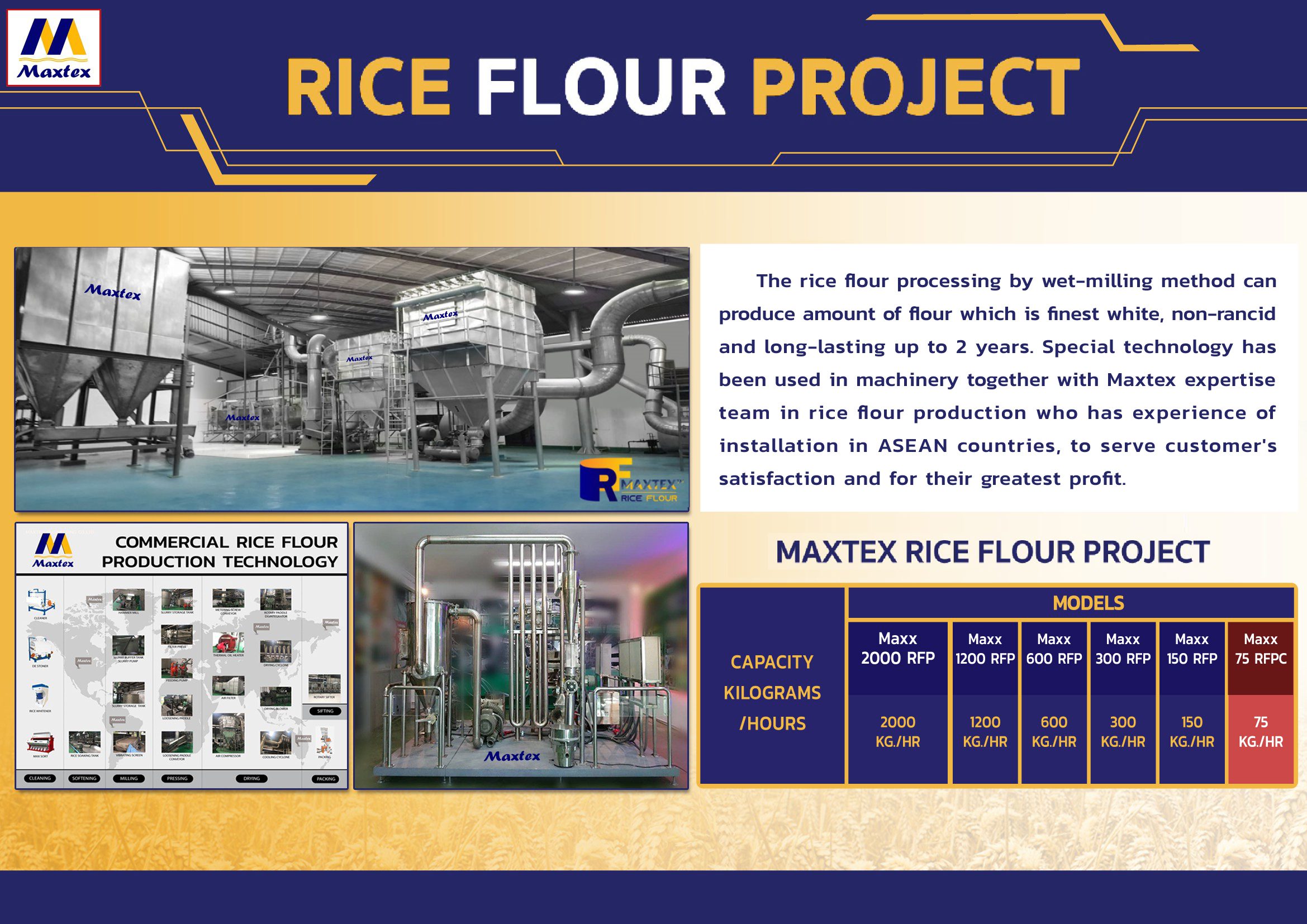

High Capacity

The production capacity is 75 – 250 kilograms per hour.

Low Cost

RFPC The machine can be easily disassembled and moved freely. It is hygienic and suitable for SMEs and startups.

Why MAXX SERIES RFPC

Maxx-Series is a unique processing solution designed to process rice into native flour by wet-milling method which gives a better quality over other flour making processes, resulting in longer-lasting, finest and best quality flour.

Why Compact Unit?

DIY easy installation Compact Unit is designed to help SME with space constrain and ease of moving between production line location.

Use only finest food grade stainless steel for structural materials and machineries according to FDA protocol.

Our unique Maxx series compact units (Maxx series capacity 75-250 kg per hour) are specifically designed to cater to smaller scale production line requiring lower volume of input raw material as compared to traditional wet milling method, large scale rice flour production which require higher input volume capacity (minimum 1,000kg) and much larger area with massive M&E installation.

Smart user friendly touch screen control panel

Other advantage of our unique design allows users to process smaller quantities required as well as the ability to change over to process different products with lesser downtime which means user can produce many types of flour products on a daily basis.

Easy and quick cleaning process according to strict hygiene standards required by various food safety authorities such as FDA, HACCP, GMP, HALAL & GHP.

Easy maintenance user friendly smart control system

Quick ROI

Why Wet milling method ?

Pioneer and global leader for smart innovation, best technology, know-how for rice flour processing.

Longest shelf life of approx. 2 years as compare to dry and semi-wet milling method.

Finest flour product achieving approx. 100 mesh and beyond.

Best in flour quality compared to flour produced by dry or semi-wet processing method.

Guaranteed to retain its natural colour and rancid free throughout its shelf life, through our unique wet method processing technology.

Viscosity approx. 300 B.U.

Able to achieve desired moisture content between the range of approx. 11% to 13%, depending on customer requirement.

Natural smell.

Input raw material goes through numerous stages of soaking and rinsing to rid of contamination before milling.

Uses special heat exchanger control temperature technology to preserve flour quality and longer shelf life.

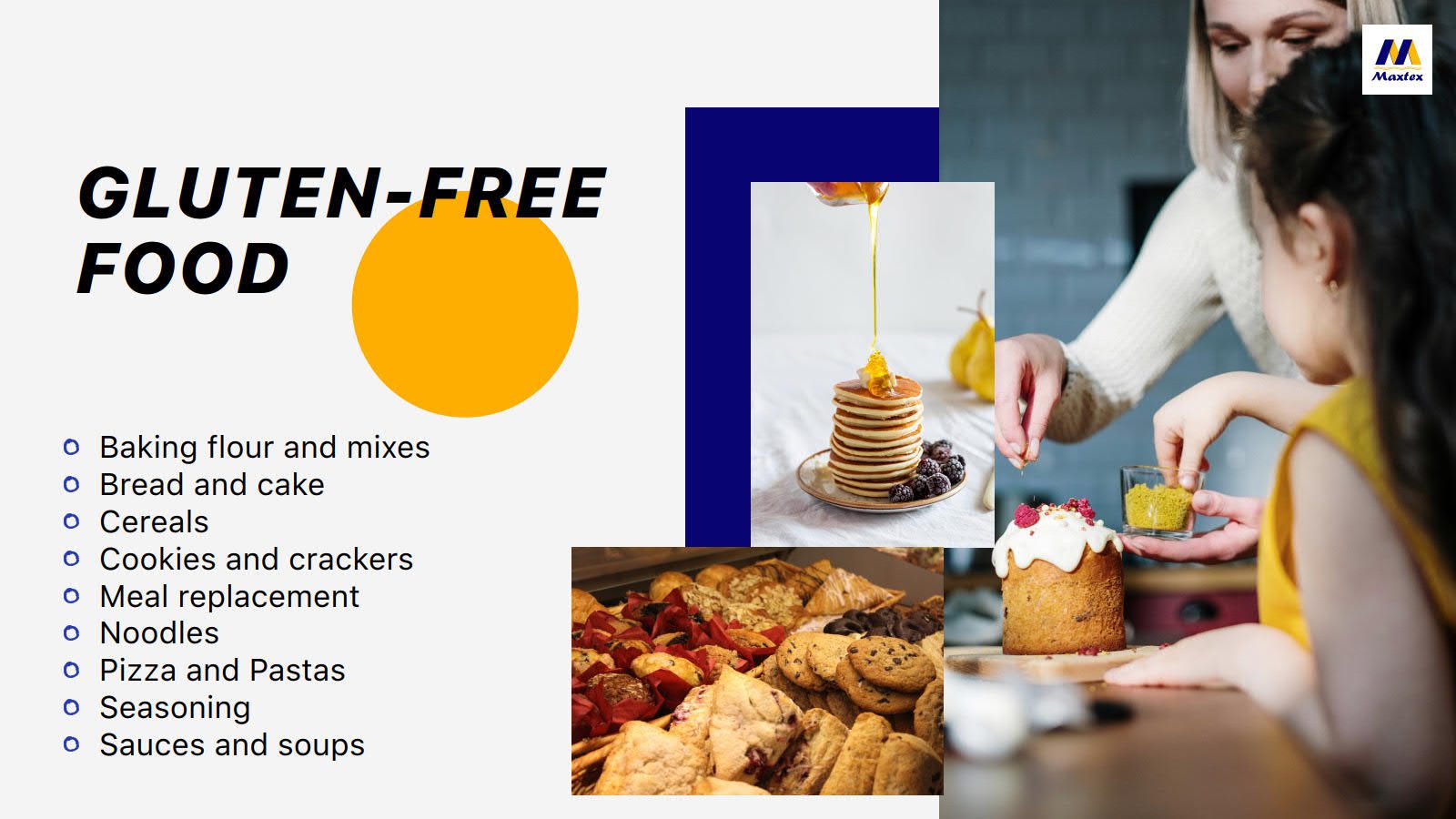

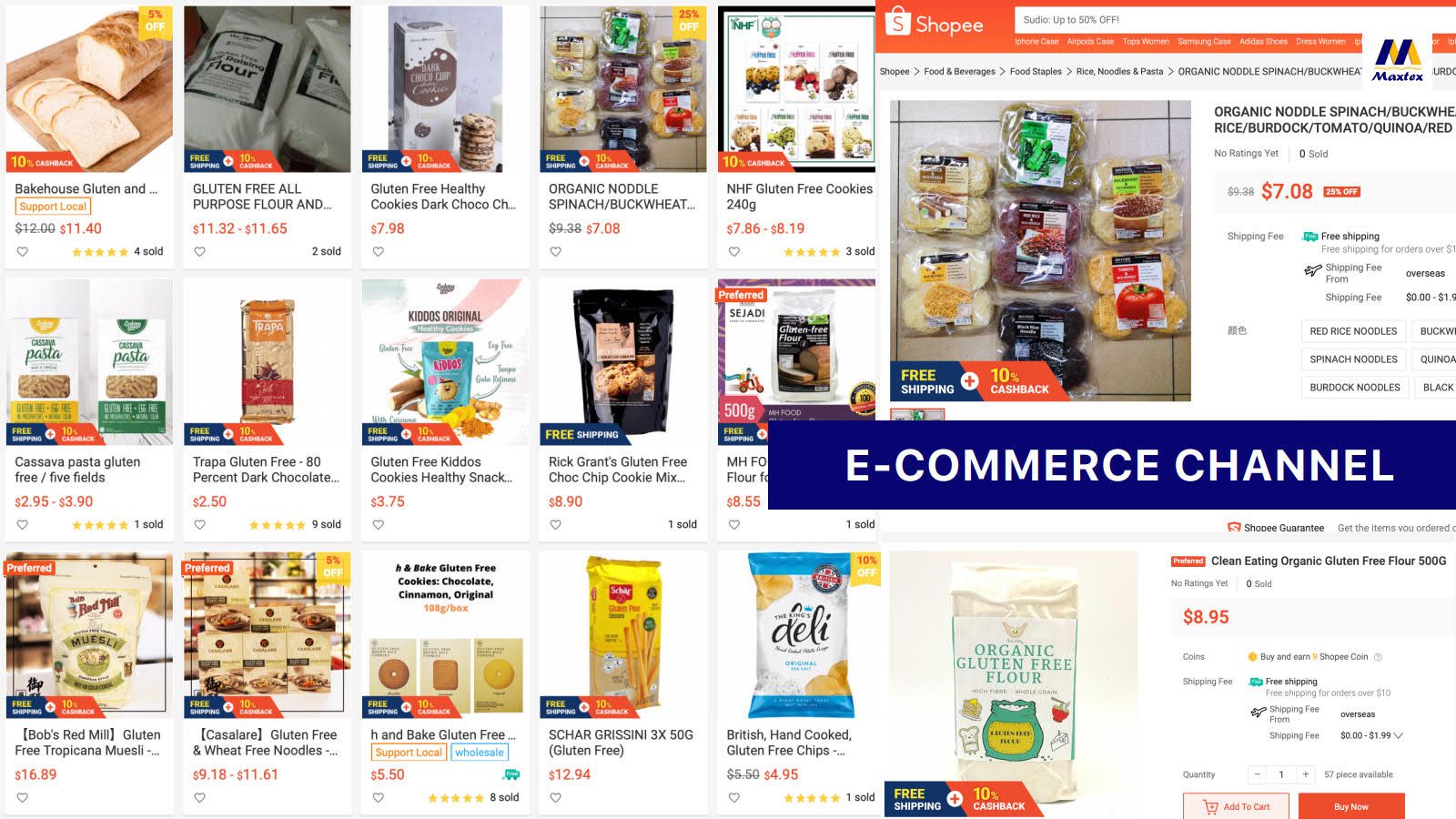

The native rice flour can be used as it is, and is often used as pre-mix with other ingredients with many applications and combination to produce savory recipes for baking, desserts, sweet, bread, pizza, tempura, etc.

Easy and quick cleaning process according to strict hygiene standards required by various food safety authorities such as FDA, HACCP, GMP, HALAL & GHP.

Gluten Free.

Cost-effective processing.

Importance of Maxtex R&D?

Maxtex unique Rice Flour Processing Compact Unit ( RFPC ) is created from our very own know-how, technology and is entirely made in Thailand. Maxx series is designed to produce world class processing platform to process and transform various types of rice to rice flour, catering to customers globally. We assure customers and consumers alike, will enjoy the best quality products. Customers who purchase Maxx Series will benefit from optimum technology with fantastic advantages such as incredible revenue with high profit margins, multiple value added solutions and quick return on investment.

Thanks to R&D team for their excellent performance, dedication and determination to create and develop to achieve the best product outcome.

R&D team with their unsurmountable knowledge have created and develop many marvelous products for the benefit of the customers and will always continue to create and develop more future products to serve the industry, business partners and consumers alike.

Maxtex R&D Team Is A Key Contributing Factor In Developing The Following;

- Research and create new products, solutions and applications.

- Continuous value add and product improvement to processing line with latest innovation and technology to decrease the operation and maintenance cost effectively.

- Maxtex R&D team also provides in-house and site training on theory, practical and machine set up, including online and live streaming training for the benefit of customers operations efficiency.

- Maxtex R&D continuously strive and source to gain valuable knowledge to constantly develop our products further and by applying digital platforms to increase our support for our customers future needs & requirement to put our customers in the forefront in the flour industry.

- Maxtex R&D team is constantly developing and creating agricultural technology sustainability, delivering value add to our valued customers for optimum benefits and spreading knowledge of rice flour processing technology to other agriculture segments.

Short Payback Period

After a short payback period, customers can invest in expanding the production line with low cost as there is no need to construct more utilities or hire more workforce.

Customers can customize the production process suitable for organic material such as organic rice, as well as millable agricultural crops such as Riceberry rice, peas, corns and grains.