MML - Multimilla Roller Mill

Wheat flour and feed production project

Maxtex introduced the project of wheat flour and feed production with IMAS of the ITTIFAK group, the European corporate giant in wheat flour and feed industry. Maxtex and IMAS had been developing business in sale and marketing in South East Asia (AEC) for more than 3 years. There are good feedbacks from both Indonesia and Vietnam. In near future, we aim to expand the sale and marketing to Thailand with close-cooperation in the development of technology industry and will generate highest benefit for both companies.

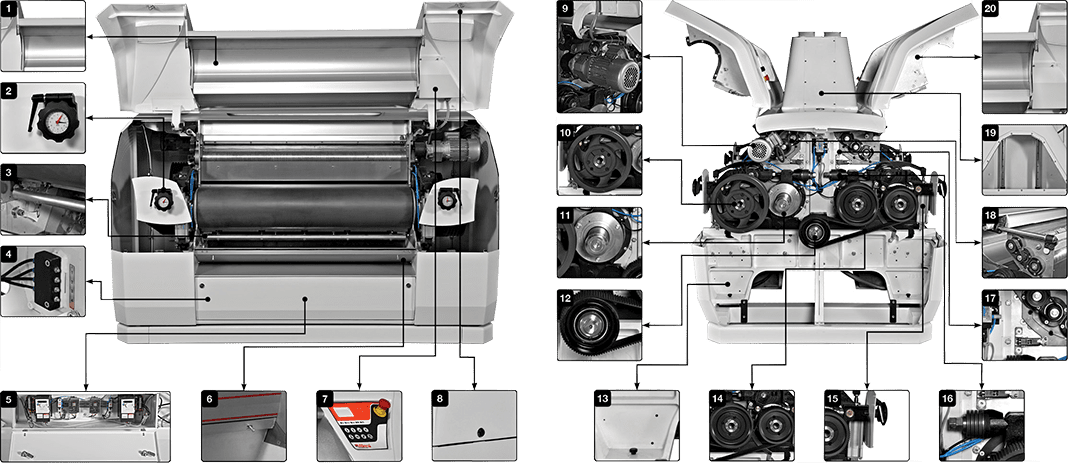

01

Aluminium Front Covers

Aesthetics and smooth surface. Easy to clean.

02

Gravity Indicator

Easy and accurate roll gap & paralleship adjustment.

03

Roll Cleaning Brusches And Knives

Easily adjustable and high-degree roll cleaning.

04

Central Greasing Systemm

It is possible to grease roll housings without stopping the roller mill which decrease the idle time

05

Electric Cabinet

Easy access to high quality electric and electronic components

06

Isolated Aluminum Product Control Gate

Light weight and easy to use, noise-free and heat-free product control gate.

07

Control Panel With High Isolation

Easy access and control of all parameters to control the roller mill. Touch-screen panel is available on request.

08

Safety Locks

To prevent unauthorised access to dangerous places the gates designed with safety locks to secure working environment.

09

Inverter Controlled Feeding Rolls

The cycle of feeding rolls are regulated automatically by invertor controlled gear motor. Optional: Alongwith automatic inverter control, the feeder rolls cycle is regulated manually by digital setting device.

10

Taper Bush Pulleys

Easy montage and dismantling. Longer lifespan.

11

Sphero-Try Phase Roll Housings

Enduring and durable housings. Aluminum housing covers prevents high temperature due to their special structure.

12

Air Regulating Valves

The amount of sucked air into machine is regulated accurately by these valves.

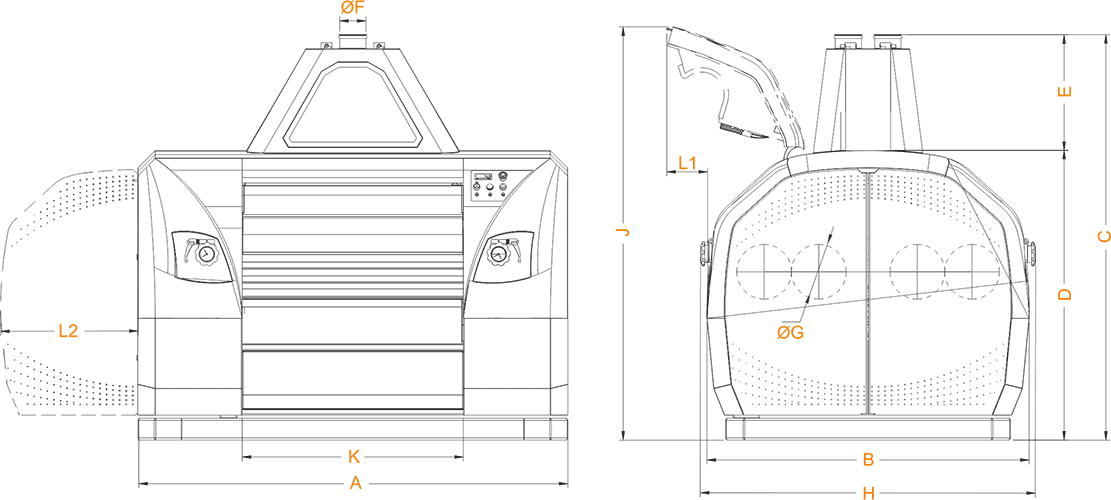

13

TRY_PARSE Iron Body

The main chassis is made of gray TRY-PARSE iron, increasing resistance and durability as well as absorbing the vibration and shocks.

14

Single Time Belt System

Longer lifespan. Easy montage and dismantling. Standard belt sizes for all roller mill types and cycle.

15

Pneumatic Control System

Strong and durable components. Maintenance free. Easy montage and dismantling.

16

Strong Disc Springs

Optimum roll grinding pressure for a constant roll space. Useful for high milling quality.

17

Aluminum Extrusion Feeding System & Roll Covers

Feeding rolls housing and roll covers are made of high-resistant aluminum extrusion profiles with bolt connection method.

18

Feeding Roll Packs With Linear Ball Bearings

Easy cleaning for the back of feeding rolls which enables maximum hygiene at minimum time.

19

Level Probes

Feeding roll cycles are adjusted automatically by means of special level probes.

20

Single-Piece Front Cover

Easy access and fast cleaning and maintenance with the completely-openable front cover.

21

Turbo System

Adjustable turbo system creates negative pressure around the rolls and provides dust absorption. In addition, dusty air is evacuated from the inlet hopper to the outlet hopper by using pneumatic system.

22

Rolls Packs For Grinding Rolls

Changing grinding rolls take only 20 minutes, thanks to completely dismantable grinding group which minimizes the idle & stop time of mill and creates time for an efficient production.